NewSpace Lab

CIM UPC

The mission of CIM UPC is to advance Digital Manufacturing through Research, Innovation, Technology Transfer and Training, putting it at the service of our society’s challenges.

Infrastructure/equipment

3D printing (FFF), Fused Filament Fabrication (FFF), ED printing (FFF) metal piece

It is used for the manufacture of prototypes or final parts. Its operation is based on a thread of thermoplastic material and an extruder that moves in the horizontal XY plane and the bench in the vertical Z plane. This thermoplastic solidifies immediately on top of the previous layer.

With this technology we can manufacture parts in green with metal (steel) that once sintered with an oven we can obtain metal parts.

Applications:

Small prototypes, gift items, gadgets…

The parts obtained can be used as prototypes in the technical office or as final parts in production processes (custom tooling), equipment (single parts), etc.

Training programmes in Digital Manufacturing.

Models and assembly of projects.

Self-manufacturing of models and final parts.

Manufacturing of multi-material and/or multicoloured parts.

3D printing, Stereolithography (SLA)

Additive technology for the manufacture of prototypes that require high precision of detail, good surface finish and appearance similar to technical plastics.

Applications:

Marketing presentations: Mirror finish identical to the final piece, ideal for promoting a product.

Suitable for final parts without high mechanical demands.

Tests with fluids, silicone moulds.

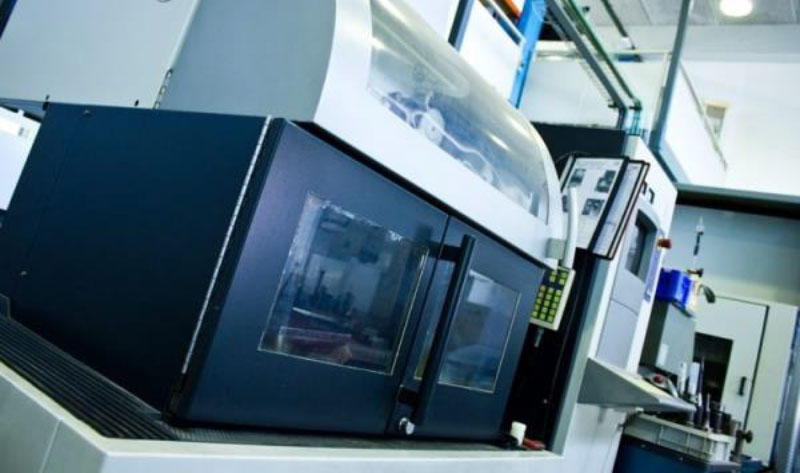

CNC machining centres, Deckel Maho DMU 50, Evolution HAAS VF 3ss, Milltronics RH20

Possibility to manufacture complex parts, with great precision and as many repetitions as necessary.

Applications:

Mechanisation of engravings.

Pieces of reduced dimensions.

Mechanisation of electrodes of reduced dimensions.

Mechanisation of reforms for thermal printing.

Wire EDM

Wire EDM machining is used to make high-precision cuts in conductive materials.

It is possible thanks to the jump in electrical discharges that takes place between the electrode and the piece to be machined. It is a thermoelectric process, in which the sparks produced represent a point thermal source that will be responsible for melting the material of the piece, thus producing erosion. In addition, deionized water is used, which will help the jump and therefore the quality of the sparks, to cool the already eroded material and to remove the torn material.

Applications:

Cutting extremely hard materials and parts without mechanical effort.

Erosion of conductive materials.

Very thick metal parts.

Very small parts such as injector pins or needles for medical use.

Pieces with very thin walls.

Cutting stacked materials.

Cutting tiny radii.

3D printing, Selective Laser Sintering (SLS)

It is used with thermoplastic materials for the manufacture of prototypes with good mechanical and functional properties that are therefore sometimes used as final parts. It uses a high-powered laser to melt plastic particles into powder layer by layer. The possibility of using composite materials with fibre (glass and carbon) and metals allows to expand its range of applications. This technology does not require support structures and allows one piece to be manufactured on top of the other.

Applications:

Product assembly validation: suitable for clips and to validate mechanisms and parts that must be assembled.

Parts with complex geometries.

Short series or final pieces in contact with aggressive liquids.

Large scale prototypes.